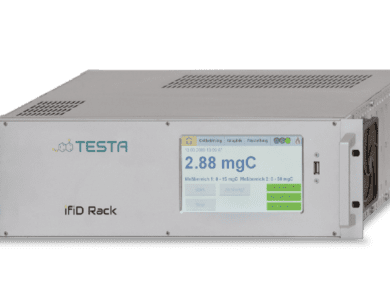

EuroFID3010 CxHy analyser

EuroFID3010 CxHy analyser

The EuroFID 3010 total hydrocarbon analyzer is a heated flame ionization detector for determining the volatile organic compounds (VOC) in exhaust air and exhaust gas. It is typically used for monitoring the LEL in drying plants and for leakage monitoring in solvent tanks. The inline analyzer can be combined with the associated control unit and terminal box to form a system.

Specifications

Measuring range

LEL: 0 ... 100 %

Measuring principle

Flame ionization detection (FID)

Ambient temperatures

0 °C ... +55 °C

Interfaces

RS-232c

Protection class

IP65

EX approval

Available for Zone I & II

Conform

ISO 60079-29-1, EN 50271

Supply voltage

115 ... 230 V / 50 ... 60 Hz

Analogue outputs

2x 0/4 ... 20mA, max. load 500Ω;

≤ 36V Potential-free

≤ 36V Potential-free

Analogue inputs

4 inputs: 0.25 ... 20V

Digital outputs

7 FET switch:

24V AC/DC, 100 mA For status signals

24V AC/DC, 100 mA For status signals

Digital inputs

3 potential-free contacts:

24V DC, 10 mA Preset for lack of gas, adjustment lock and maintenance lock

Vooraf ingesteld voor gasstoringen, afstelproblemen en onderhoudsproblemen

24V DC, 10 mA Preset for lack of gas, adjustment lock and maintenance lock

Vooraf ingesteld voor gasstoringen, afstelproblemen en onderhoudsproblemen

Detection limit

< 1.5 % of measuring range full scale

EN14181 QAL1 certificate

Yes

EN 15267-3 certificaat

Yes

Measuring gas temperature

≤ +350 °C

Dimensions (H x W x D)

210 x 275 x 887mm

Display

LC-display

Weight

≤ 25 kg

Electrical safety

CE, cCSAus

Downloads

Brochures

Certificates

Features:

- Gas warning device for volatile organic compounds

- Certified to EN 50271

- Inline type for direct coupling with the process

- Optional housing for use in Ex zones 1 and 2

- Modular design for flexible installation

- Integrated dilution of sample gas

- All gas paths are heated

- No moving parts

Benefits:

- Early warning thanks to short response time

- Measurement in corrosive gases possible

- No condensation inside the analyzer due to heating and dilution of measurement gas

- Low maintenance effort due to wear-resistant design

- Direct mounting at the gas duct possible

- EU-type examination as gas warning device according to 94/9/EC

Applications:

- Monitoring of VOC concentration in raw gas upstream of systems for cleaning exhaust air

- LEL monitoring in the production of solvent-based products

- LEL monitoring in dryers in coating systems

- LEL monitoring for spray booths

- Leak detection for solvent-filled containers