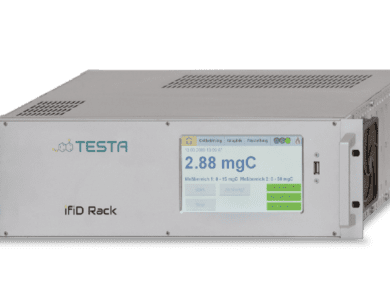

MCS300P Multi Component Process Analysis System

MCS300P Multi Component Process Analysis System

MCS300P – Simultaneous process monitoring of up to 6 measuring components

The MCS300P is an extractive process photometer for measurement of gaseous or liquid media. It measures IR- and VIS-active components with variable measuring ranges from very low (ppm) to high (vol%) concentrations. For monitoring of toxic or flammable mixtures, it has special process cuvettes with safety devices like twin-seals and purge gas feeds. The heatable cuvettes made of corrosive-resistant materials have a high pressure resistance. An automatic adjustment device an innovative operation concept and modern communication protocols make the MCS300P an all-purpose photometer, also for potentially explosive atmospheres.

The heated system components prevent a temperature drop below the water and acid dewpoint. This results in lower maintenance and higher reliablity and long-time stablity of the system, also under rugged and demanding conditions. Automatic adjustment functions, easy operation concept and modern communication protocols results in a quick and easy integration into a local control system network.

Specifications

Temperature change maximum ±10 °C/h

With cooling device: +5 °C ... +45 °C

Electrically isolated, additional outputs if using I/O modules (option)

Electrically isolated, additional inputs if using I/O modules (option)

3 potential-free contacts: Additional outputs if using I/O modules

2 power relays: Electrically isolated, additional outputs if using I/O modules (option)

Additional inputs if using I/O modules

Status-LED's: *Power*, *Maintenance* and *Failure*

Downloads

Features:

- Simultaneous measurement of up to 6 components plus O2

- Sample flow control and sample gas pressure measurement

- Temperature of heated system components up to 220 °C

- Automatic sample point switching for up to 8 sample points (option)

- Automatic adjustment of zero and span point

- Integrated adjustment unit without span gas (option)

- Extended operation via PC and software

- Flexible I/O modules

Benefits:

- Economic, automatic adjustment without expensive test gases

- Easy remote control by integration in existing networks

- Automatic control of the complete measuring system and probe

- Low maintenance and reliable due to hot measurement

- In combination with probe SCP3000 also for measurements at high dust loads and high temperatures

- Short response time due to high sample gas flow

Applications:

- Process control in chemical production, e.g. of vinylchloride, isocyanate, polycarbonate, acrylic acid, adipic acid

- Raw gas monitoring in waste incineration

- Process control in the chemical industry

- Monitoring of exhaust gas purification plants

- Monitoring of flue gas conditioning in waste or sewage sludge incinerators

- Monitoring of the scrubber in flue gas conditioning

- Measurement directly at the kiln inlet in cement plants