MCA10 Emission Monitoring System hot wet CEMS

NDIR Multi Component Analysis System: CEMS MCA10

The MCA10 CEMS from Dr. Fodisch is based on NDIR and FID technology. The MCA10 is an analysis system that performs all tasks for accurate emission monitoring. More than 10 components can be measured simultaneously.

A main goal of this CEMS MCA 10 development is to realize an analyzer with low maintenance requirements. At the same time, the system has a high analysis accuracy for components such as: HCl, HF, SO

FID analyser

The CEMS MCA10 has recently been TÜV approved. Including a total hydrocarbons (CxHy) FID analyzer. This is an FID analyzer whose detector directly branches off the sample from the sampling line. An advantage is that you do not need a separate sampling line and sampling probe. This FID analyzer has also been tested based on NEN-EN 15267-3 by the TÜV. The analyzer is part of the TÜV certificate.

Automatic calibration

Unique to the MCA10 is that it can be equipped with the option of fully automatic calibration. To achieve this, a so-called “optical filter wheel” is built in. This makes calibrations possible without the use of calibration gases. Of course, entirely in accordance with the QAL3 EN14181:2014 standard.

This gives you two important advantages for the CEMS: an economic advantage and higher availability. The economic advantage lies mainly in the fact that no costs are incurred for calibration gases, cylinder rental, depreciation and reduction. In addition, the calibration with the optical filter wheel is fully automatic and therefore no man-days are required. The start of this calibration cycle can even be initiated by the emission registration systee.

Specificatons

27.BImSchV, TA-lucht, EN 15267,

EN 14181, MCERTS

Number depends on system configuration, galvanically isolated, max. 32 inputs

Status-LED's: *Power*, *Maintenance* and *Failure*

Downloads

Brochures

Handleidingen

Technical Questionaire

Characteristics CEMS MCA10

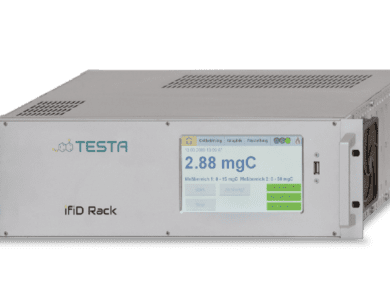

- Operation via touchscreen

- Automatic adjustment of the MCA10 analyzer

- Automatic backwashing and filter cleaning of the sampling unit

- Measurement of up to 10 IR components plus O2 and total hydrocarbons (CxHy)

- Extractive analysis method

- Low-maintenance gas transport using an ejector pump

- Calibration with internal calibration filter wheel

- Certified digital Modbus® interface

- Simple remote control via Teamviewer or VNC

- Modular construction

Benefits MCA10

- Real limit value monitoring

- CO, NO, NO2, N2O, SO2, HCL, HF, NH3, CH3, CO2, H2O, O2 and CxHy certified

- According to EN 15267-1:2009, EN15267-2:2009, EN15267-3:2007 and EN14181:2014

- Only one analyzer for 12 measuring components

- Easy to integrate into the customer’s network environment

- Long maintenance interval of 6 months for many measuring components

- Suitability tested measurement of greenhouse gases such as N2O, CH4 and CO2

- Low maintenance costs

- Low certified measuring range for NO

- Performance comparable to FTIR technology

- Mirrors arranged vertically

Applications CEMS MCA10

- Emission monitoring at waste incineration plants

- Power plants

- Process analyzer

- Includes combustion plants, e.g. cement factories

- Measurement of nitrogen oxides (NO, NO2, N2O and NH3)